QDP, Inc. is excited to announce the recent expansion of our facility, which adds an additional 3,000 sq. ft. of manufacturing space adjacent and connected to our existing 8,700 sq. ft. facility. Several updates were made to the addition including new electric service, a fresh coat of paint, and a new floor. All building improvements were optimally configured to facilitate our expanding capabilities, including in-house tool and die making, large capacity precision CNC machining, and wire EDM.

Author Archives: QDP Inc.

As with all of our endeavors, quality and precision were the main driving forces behind sourcing the new machines, and they are super-precise! Additionally, we hired Matt Silvano whose 30 plus years of engineering, toolmaking and CNC machine programming and operating experience working with the exact machines we purchased ensured proper installation, setup, and ongoing…

There are many things to consider when choosing a precision stamping supplier, especially when the material specified is thin film, extra light gauge metal, or a thin film lamination. In this post we highlight the top 5 considerations that every company should factor into their decision during their supplier evaluation and selection process.

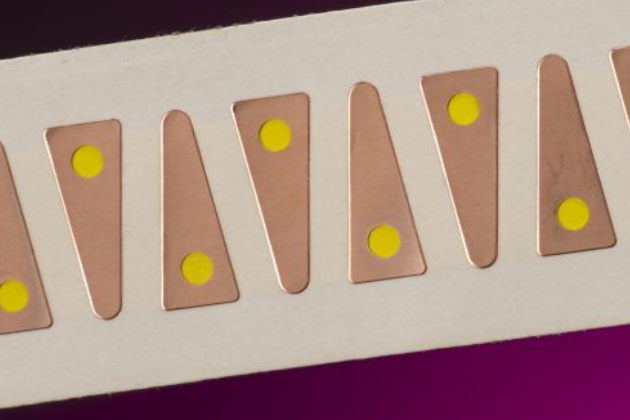

When specifications for cutting thin film laminations call for a high level of precision and/or complex shapes, the process of stamping the laminations produces a much more precise, repeatable, and accurate result. Thin film laminating is the process of applying adhesive to 2 or more layers of thin film or metal substrates and combining them to form a “lamination”.

When customers require quality improvements in manufactured thin film components, QDP is the place to turn for the solution. One such opportunity presented itself to us when a customer required the extremely tight tolerances of +/-.005” slit widths in laminated films. Their previous supplier was not able to meet these tolerances at all.

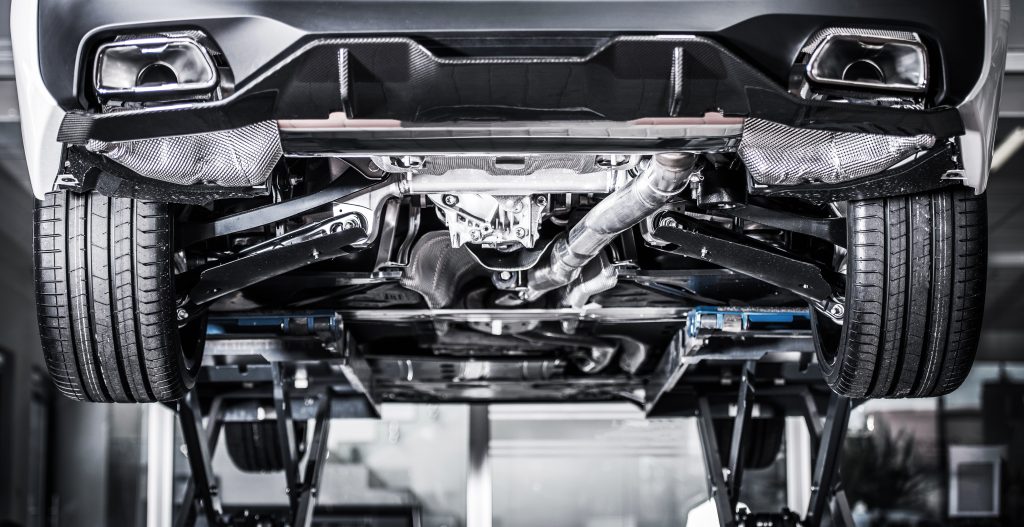

A major OEM automotive parts manufacturer turned to QDP to solve a concern they were having regarding the level of safety in the heat shields they manufacture. Tens of thousands of aluminum heat shields are manufactured each year and installed on vehicles of different models, oftentimes in difficult to reach places. There was a concern that the edges of the heat shields were too sharp and may put the people who install and provide maintenance on these parts at risk for accidental lacerations.

QDP has leveraged its rich history of thin foil stamping for the hard disk drive (HDD) industry to provide similar services across the electronics industry at large. In particular, stamping of thin foil shielding materials is in growing demand. It is critical that precision specifications be consistently satisfied as the major push in the electronics industry is to develop higher performance in a smaller footprint. These demands influence impact component manufacturers who are tasked with producing parts that ultimately satisfy the overall product feasibility.

QDP Inc. is pleased to announce that we are ISO 9001:2015 certified (view the QDP ISO 9001:2015 Certification here). The scope of the certification covers “The manufacture of precision stamped parts and laminated rolled goods”. The six month process to upgrade from ISO 9001:2008 was completed in 2017 with a certification dated March 26, 2018….

Where can manufacturers go for superior Quality, Delivery, and Price in stamping? They go to QDP, Inc. Based in Pennsylvania, QDP is a single source provider that designs, builds, and runs stamping for metal and plastic. They also offer adhesive laminating and slitting of metal and plastic film. QDP has a history of pushing the…

On August 16, 2016 we received an email from Eric Babbitt, Manufacturing Engineer for Burris Optics. Eric explained that Burris was having quality issues with plastic shims used in the manufacture of their scopes, the main problem was debris from the burrs on the shims which came off during assembly and testing. Eric wanted to…

- 1

- 2