There are many things to consider when choosing a precision stamping supplier, especially when the material specified is thin film, extra light gauge metal, or a thin film lamination. In this post we highlight the top 5 considerations that every company should factor into their decision during their supplier evaluation and selection process.

Tag Archives: qdp inc

When specifications for cutting thin film laminations call for a high level of precision and/or complex shapes, the process of stamping the laminations produces a much more precise, repeatable, and accurate result. Thin film laminating is the process of applying adhesive to 2 or more layers of thin film or metal substrates and combining them to form a “lamination”.

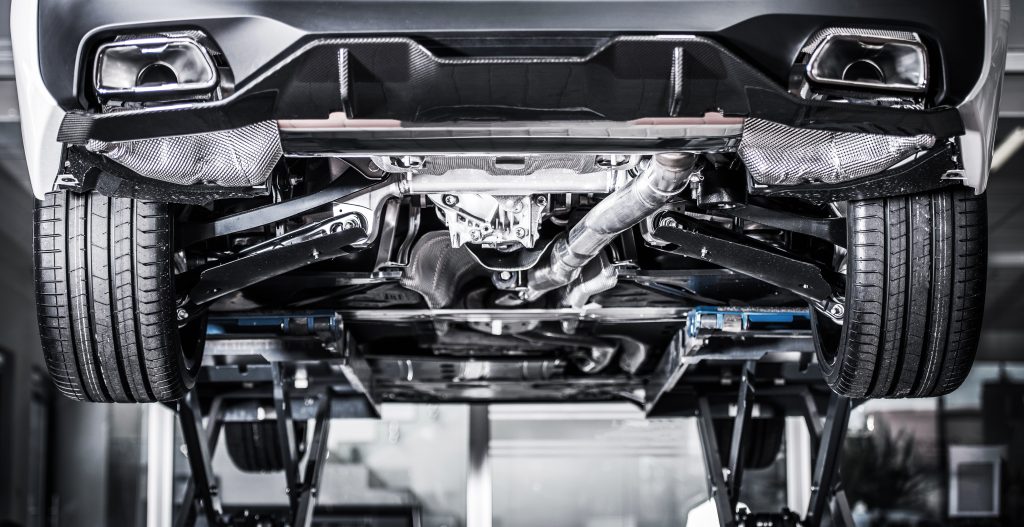

A major OEM automotive parts manufacturer turned to QDP to solve a concern they were having regarding the level of safety in the heat shields they manufacture. Tens of thousands of aluminum heat shields are manufactured each year and installed on vehicles of different models, oftentimes in difficult to reach places. There was a concern that the edges of the heat shields were too sharp and may put the people who install and provide maintenance on these parts at risk for accidental lacerations.

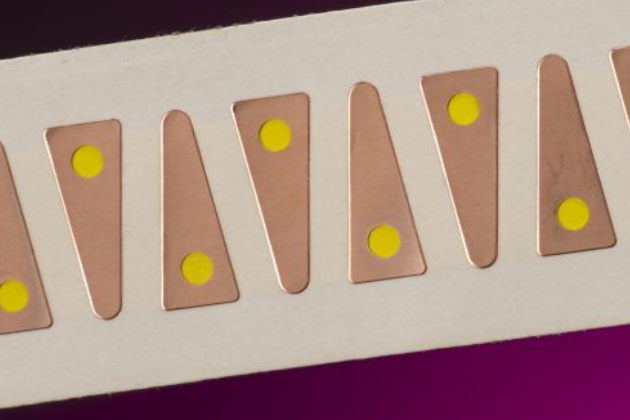

QDP has leveraged its rich history of thin foil stamping for the hard disk drive (HDD) industry to provide similar services across the electronics industry at large. In particular, stamping of thin foil shielding materials is in growing demand. It is critical that precision specifications be consistently satisfied as the major push in the electronics industry is to develop higher performance in a smaller footprint. These demands influence impact component manufacturers who are tasked with producing parts that ultimately satisfy the overall product feasibility.