Client: Geospace Technologies Industry: OEM/Technology Geospace Technologies is a leading provider of technologies for seismic data acquisition and various other industrial applications. For a critical product line requiring specialized components, Geospace needed shielding components stamped from their specified material which was a plastic film laminated metal. Although the part size was considerably larger than the…

Category Archives: Case Studies and Testimonials

When customers require quality improvements in manufactured thin film components, QDP is the place to turn for the solution. One such opportunity presented itself to us when a customer required the extremely tight tolerances of +/-.005” slit widths in laminated films. Their previous supplier was not able to meet these tolerances at all.

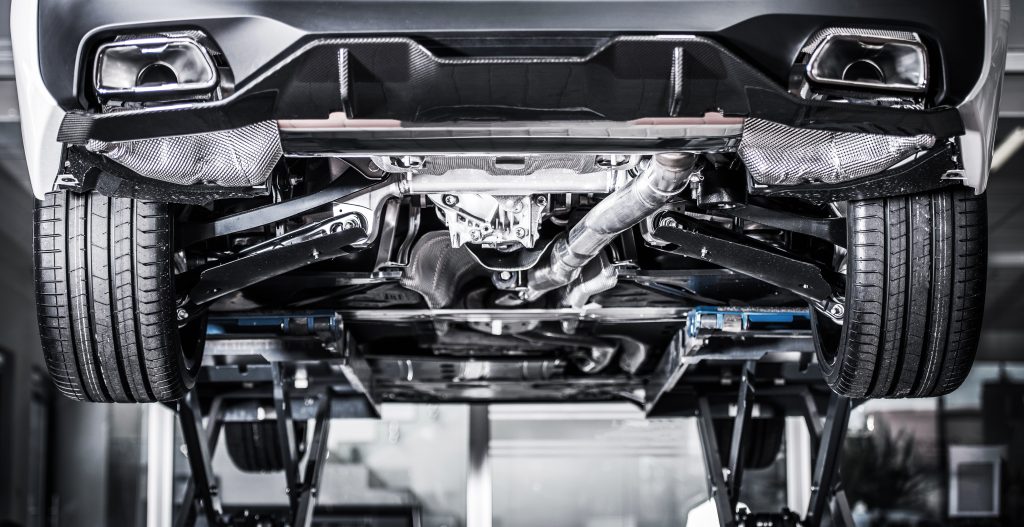

A major OEM automotive parts manufacturer turned to QDP to solve a concern they were having regarding the level of safety in the heat shields they manufacture. Tens of thousands of aluminum heat shields are manufactured each year and installed on vehicles of different models, oftentimes in difficult to reach places. There was a concern that the edges of the heat shields were too sharp and may put the people who install and provide maintenance on these parts at risk for accidental lacerations.

On August 16, 2016 we received an email from Eric Babbitt, Manufacturing Engineer for Burris Optics. Eric explained that Burris was having quality issues with plastic shims used in the manufacture of their scopes, the main problem was debris from the burrs on the shims which came off during assembly and testing. Eric wanted to…