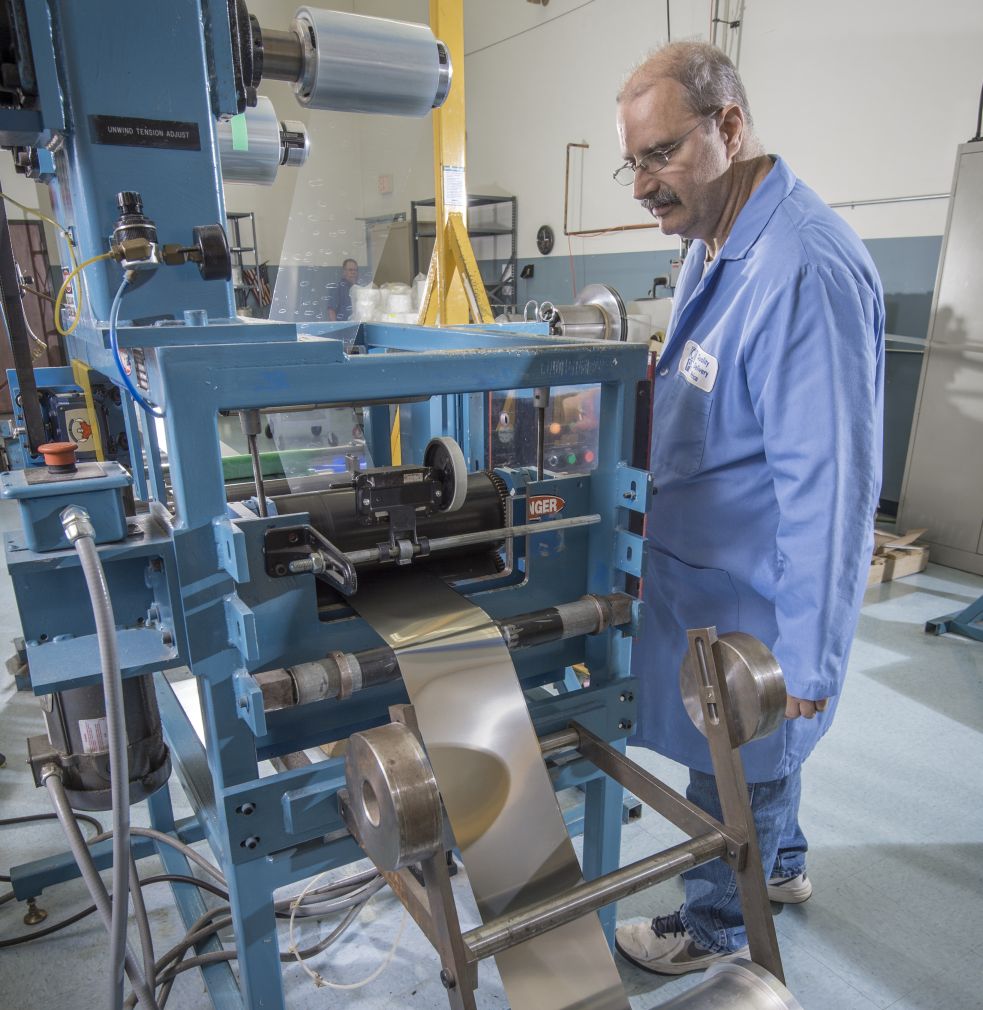

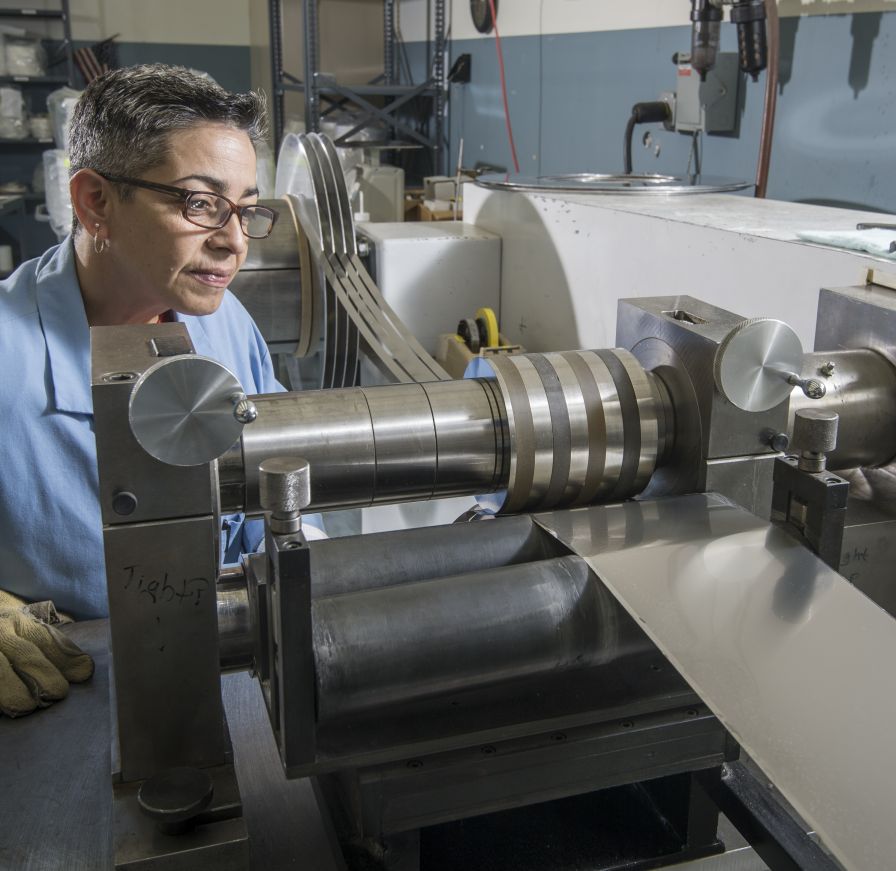

Metal Laminating & Slitting

QDP offers cleanroom adhesive lamination and ultra-precise slitting for a wide range of metals, including stainless steel, copper, and aluminum. With in-house adhesion testing, application-specific adhesive selection, and slitting tolerances as tight as ±.001”, we deliver high-performance materials.