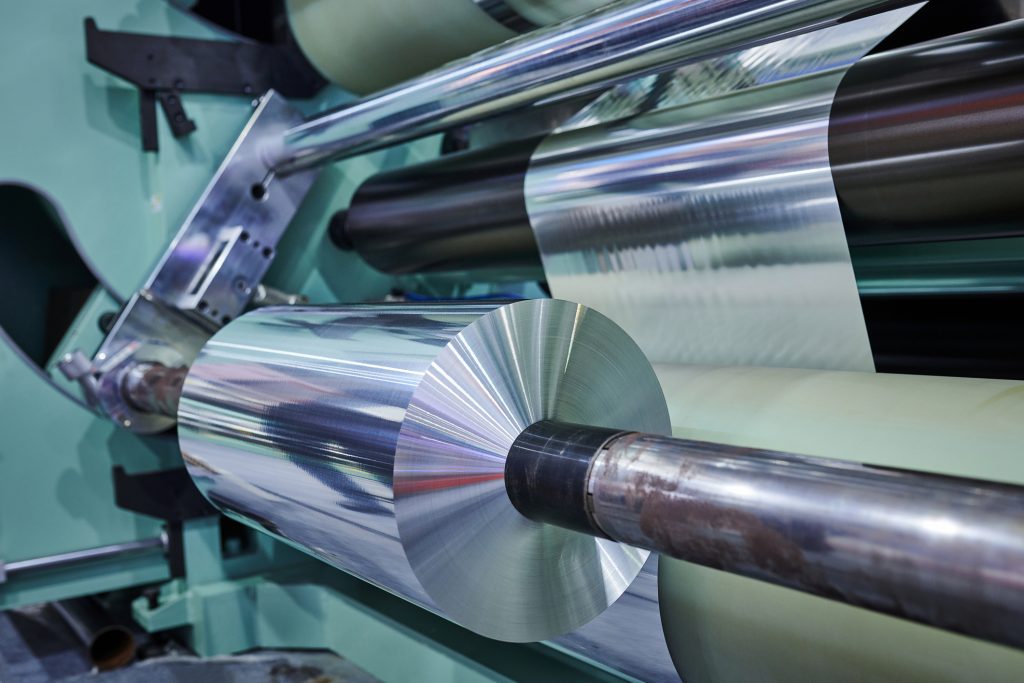

Precision Cut-to-Length Services for Thin Metals

We specialize in precision cut-to-length services for thin metals, offering unmatched

accuracy, consistency, and care in handling delicate materials. Whether you need parts

for electrical laminations, shielding, or other high-performance applications, our

proprietary processes deliver results that meet the most demanding specifications.