Precision Laminate Stamping

QDP specializes in precision-stamped, adhesive-laminated components made from plastic films, stainless steel, and specialty materials—engineered for applications that demand extreme accuracy, cleanliness, and performance.

QDP specializes in precision-stamped, adhesive-laminated components made from plastic films, stainless steel, and specialty materials—engineered for applications that demand extreme accuracy, cleanliness, and performance.

We have the expertise and equipment to produce any part configuration from stock films, foils, metals, and papers to newly developed niche materials while upholding the most critical tolerances. If your current rotary or steel rule die-cut parts barely meet specifications, let us evaluate them—chances are we will be able to improve:

The stamped parts shown here are film/adhesive laminated components designed for hard disk drives. They are made from a .002” thick plastic film laminated with a .002” thick adhesive. As the image illustrates, these parts can be extremely small.

To ensure absolute cleanliness and contamination-free production, all manufacturing and packaging take place in a cleanroom environment.

All these parts were stamped, placed on a continuous strip, and wound onto reels using QDP’s proprietary process. For reference, they are displayed on a penny to highlight their miniature size.

If you’re working with ultra-thin materials, demanding tolerances, or intricate laminated parts, QDP has the expertise to deliver. Share the details of your project, and we’ll provide a custom quote backed by proven cleanroom processes and decades of precision lamination and stamping experience.

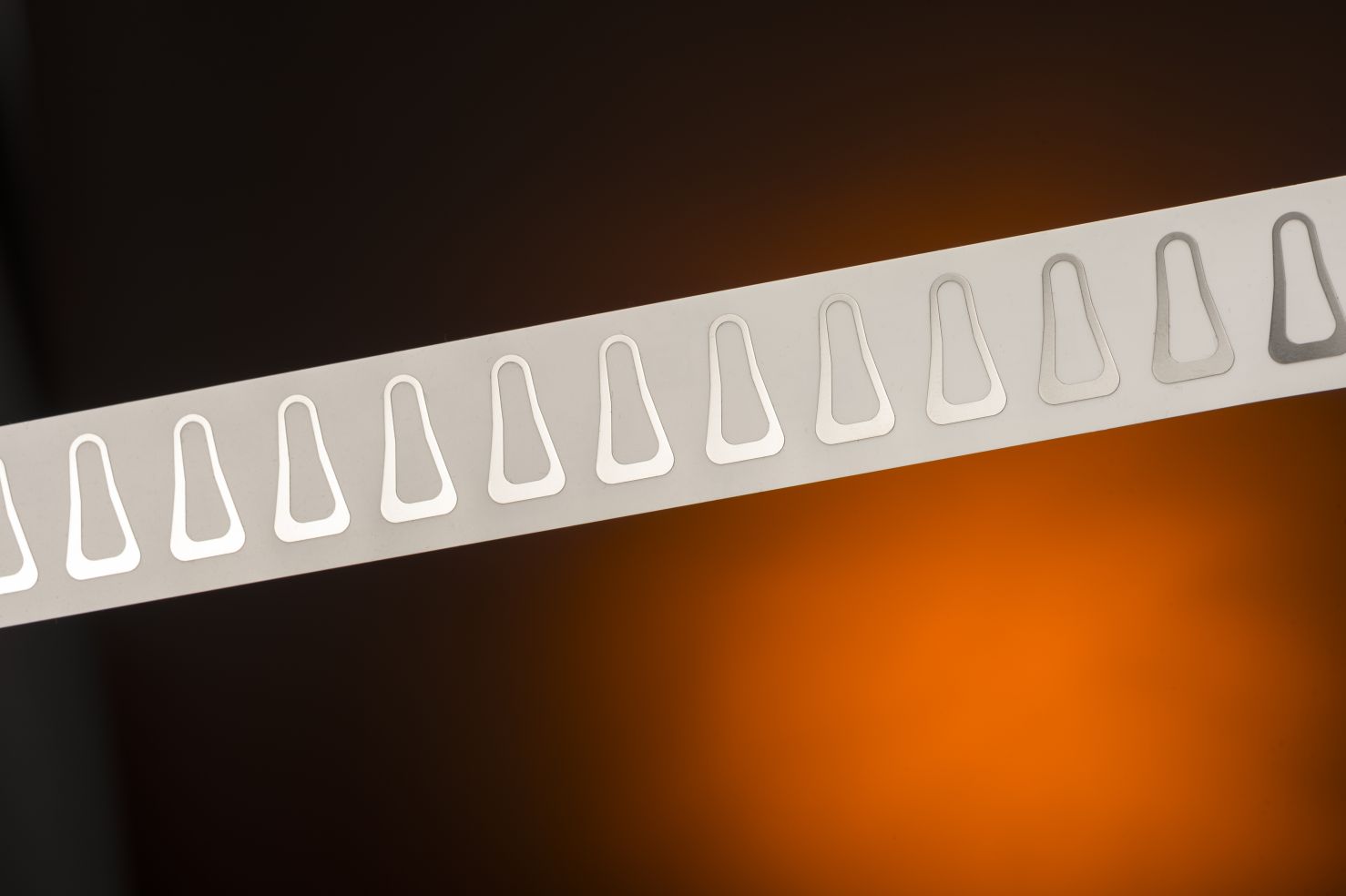

These Stainless Steel/adhesive laminated parts are also designed for hard disk drives.

Similar to the plastic film parts, these components must remain perfectly clean, so all processes, including packaging, are conducted in a cleanroom.

These parts are supplied on rolls with a plastic film release liner, which can include pilot holes for seamless integration into automated assembly lines.

To ensure easy handling and assembly, adhesive-laminated parts—whether metal or plastic film—are supplied on tape rolls.

The image showcases a variety of precision-stamped small laminated parts, including: