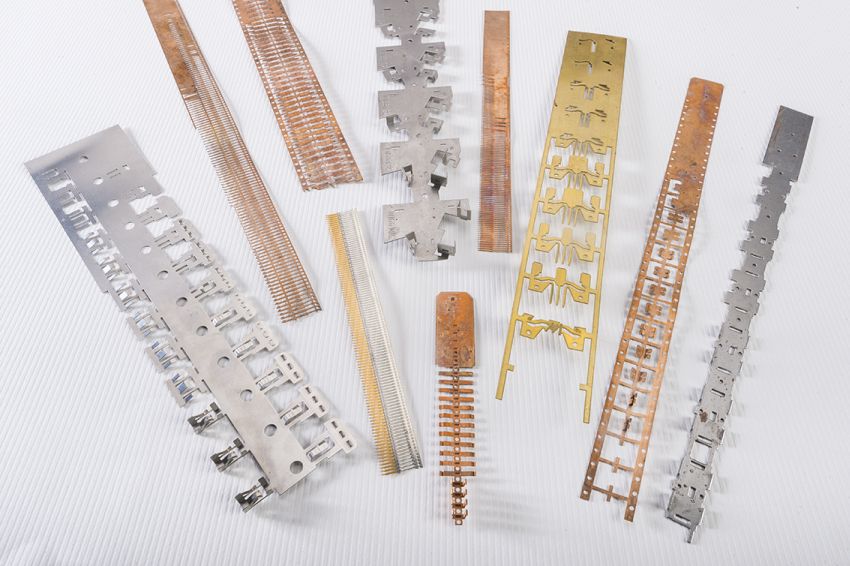

Progressive Die Strips

These precision stamped die strips are made from many different materials including Phosphor Bronze, Brass, Copper, CRS, and SST. One of the unique features of the stamping tooling designed and built by QDP is that we typically build dies that are more compact than most other shops. One obvious advantage is the cost savings in tool material costs which is passed along to our customers. Because our die designs are proprietary, our customers typically only pay for 50% of the tooling cost. QDP retains ownership of all tooling that is designed and built by us. Because of this the customer never pays for any maintenance or repairs on the tool for the projected life of the tool based on the customer forecast.

Reel to Reel Parts

In the electronics industry, and especially the connector industry, it is necessary to run parts as a continuous strip and wrapping the parts onto a reel. This is done primarily for three reasons: (1) to facilitate selective plating, especially gold or palladium. After plating, the strips are run through dies to do secondary forming and then cut the parts free from the strip. This is usually done when the parts can be fed as loose parts in vibratory feed bowls for insertion into a base; (2) to allow for gang loading of parts into a base. This could be either plated or un-plated parts; (3) to keep the parts on carrier strip, to facilitate locating parts in molds that are to be over-molded. Running reel to reel does require some expertise to achieve acceptable results and QDP has the experience. Another critical factor in running reel to reel especially when the parts are to be gang loaded is the ability to hold the advance from part to part very closely. e.g. If the pitch between parts was .050” and there were 40 parts being inserted at a time, if the advance was off by .0002” the parts could be off by .008” overall. We have typically held parts to .0005” total accumulation over a 2 inch long strip.(40 advances)

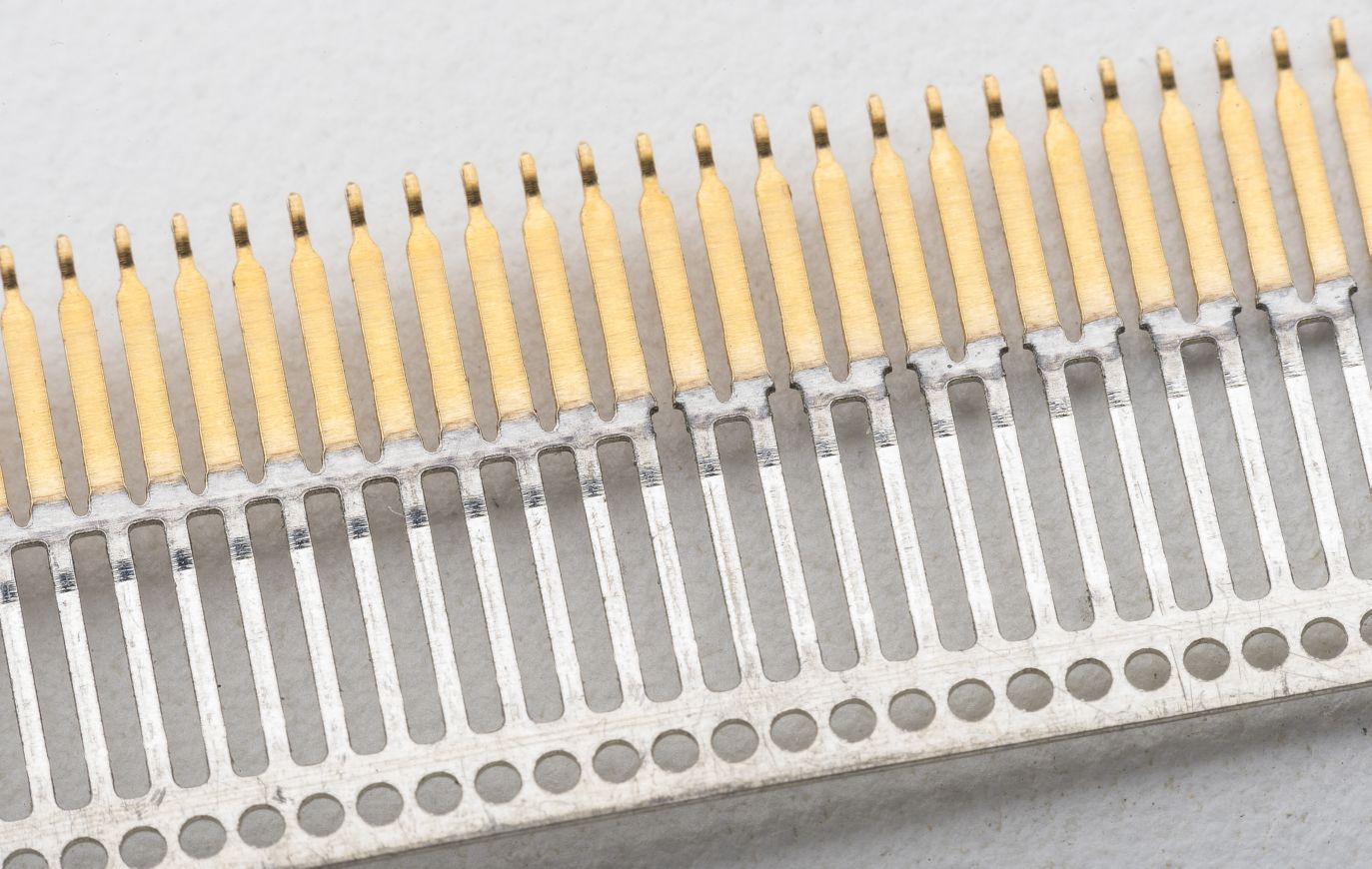

Extreme Ratio Blanking

The simplest description of EXTREME RATIO BLANKING is blanking a shape through a material where the smallest section of the shape being blanked is less than two times the thickness of the material being blanked. e.g. If the material being blanked is .010” thick any hole smaller than .020” would be considered extreme ratio blanking. In this example the material is .012” thick Phosphor Bronze A and the slot at the end is .007” wide and .045” long. To put this into perspective, it would be the equivalent of blanking a .072” dia. hole through .125” thick material or a .145” dia. hole through .250” material. Most stamping companies would tell you it can’t be done but QDP has the expertise and experience needed to do it successfully. If you have ever wished you could design in this type of configuration into your job and thought it was not feasible, ask us before you dismiss your idea.

Medical Connector Part

These medical connector parts were stamped from .012” Stainless Steel. The die has 8 blanking operations, 5 lancing operations, 4 forming operations and a cutoff operation. The entire working area of the die is only 10 inches. This is due to QDP’s unique die design and is 30-50 percent shorter with fewer advances than most shops would design and build. This equates to lower tool building and maintenance costs. If you have a part with unusual profiles and/or forms let us take a look at it and see if we can produce your part within your budgetary constraints.